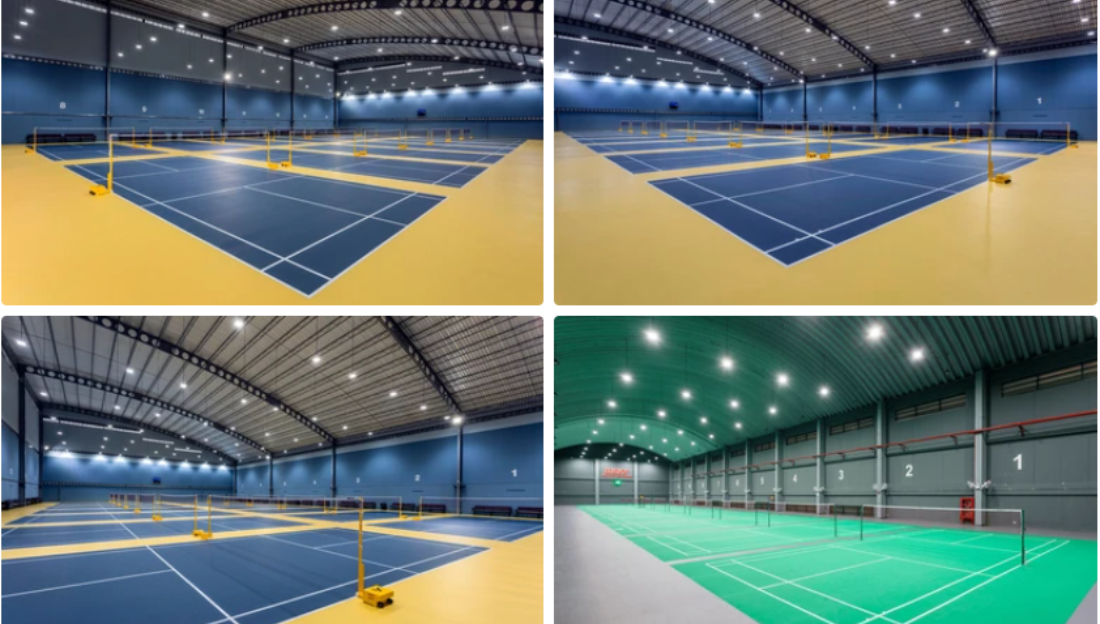

When it comes to warehouse operations, proper lighting plays a crucial role in ensuring efficiency, safety, and productivity. Whether you're managing a distribution center, manufacturing facility, or storage space, having the right lighting system can make a significant difference. But what exactly is the standard lighting for a warehouse? Let’s break it down.

Importance of Proper Warehouse Lighting

-

Safety: A well-lit warehouse minimizes accidents by improving visibility, reducing slips, trips, and falls.

-

Productivity: Proper lighting helps employees see clearly, reducing eye strain and fatigue.

-

Energy Efficiency: Using the right type of lighting can help lower electricity costs and reduce environmental impact.

-

Compliance: Many regulatory bodies, such as OSHA, have specific requirements for warehouse lighting to ensure worker safety.

Standard Warehouse Lighting Requirements

The standard lighting level for a warehouse depends on its function and tasks performed within the space. However, here are general guidelines:

-

General Storage Areas: 10-30 foot-candles (fc) or 100-300 lux.

-

Packing & Sorting Areas: 30-50 fc or 300-500 lux.

-

Detailed Work Areas: 50-75 fc or 500-750 lux.

-

Emergency Lighting: Should be sufficient to allow safe evacuation, typically around 1-10 fc.

Types of Warehouse Lighting

-

LED Lighting: Highly energy-efficient, long-lasting, and provides bright illumination with minimal heat output.

-

High-Intensity Discharge (HID) Lamps: Includes Metal Halide and High-Pressure Sodium lamps, traditionally used but now being replaced by LEDs.

-

Fluorescent Lighting: Cost-effective and energy-efficient, suitable for lower-ceiling warehouses.

-

Natural Lighting: Skylights and windows can supplement artificial lighting and reduce energy consumption.

Factors to Consider When Choosing Warehouse Lighting

-

Ceiling Height: High ceilings require high-lumen output fixtures like High Bay LED Lights.

-

Light Color Temperature: A color temperature of 4000K-5000K is ideal for a bright, daylight-like feel.

-

Motion Sensors & Smart Controls: These help reduce energy waste by adjusting lighting based on occupancy.

-

Durability: Consider fixtures that are resistant to dust, moisture, and extreme temperatures.

Conclusion

Selecting the right lighting for your warehouse is essential for maintaining a safe, efficient, and cost-effective workspace. LED lighting is often the best choice due to its durability, brightness, and energy savings. By following standard lighting requirements and considering your warehouse’s specific needs, you can create an optimal lighting environment that enhances operations.

Need help choosing the best lighting for your warehouse? Consult a lighting expert to find the best solution for your facility!