Proper lighting in a warehouse is crucial for ensuring safety, efficiency, and productivity. The right warehouse lighting enhances visibility, reduces accidents, and optimizes workflow. In this guide, we will explore the light requirements for warehouses, industry standards, and how to choose the best warehouse lighting solutions.

Importance of Proper Warehouse Lighting

Warehouses are high-traffic environments where workers operate heavy machinery, store products, and manage inventory. Poor lighting can lead to errors, injuries, and inefficiencies. High-quality LED warehouse lighting and well-planned light distribution improve workplace safety and efficiency.

Warehouse Light Requirements Based on Industry Standards

The Illuminating Engineering Society (IES) and Occupational Safety and Health Administration (OSHA) provide guidelines for warehouse lighting. The recommended light levels depend on the specific tasks performed in different areas of the warehouse.

General Warehouse Lighting Standards

| Warehouse Area | Recommended Lux Levels (lx) | Foot Candles (fc) |

|---|---|---|

| General Storage | 100-200 lx | 10-20 fc |

| Packing Areas | 300-500 lx | 30-50 fc |

| Loading Docks | 150-250 lx | 15-25 fc |

| Inspection Areas | 500-750 lx | 50-75 fc |

| Office Spaces | 400-600 lx | 40-60 fc |

The lux level (lx) measures the amount of light per square meter, while foot candles (fc) measure light intensity per square foot. Adequate illumination ensures accuracy in work operations and reduces strain on workers’ eyes.

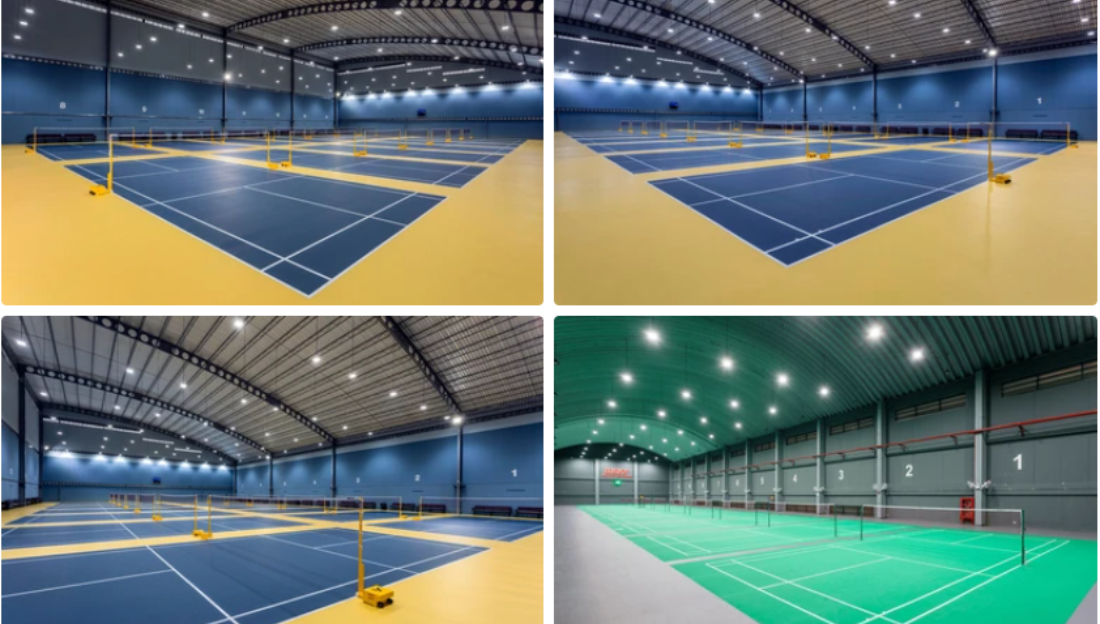

Best Lighting Solutions for Warehouses

1. LED Warehouse Lighting

LED lights are the preferred choice for warehouses due to their energy efficiency, durability, and low maintenance. They provide bright, uniform illumination, reducing shadows and glare.

2. High Bay Lighting Fixtures

For warehouses with high ceilings (above 15 feet), High LED Bay Lights are ideal. They offer powerful, long-range illumination, making them suitable for large storage spaces and work areas.

3. Motion Sensor Lighting

Motion-activated lights help conserve energy by turning on only when needed. These are especially useful in low-traffic zones or during off-peak hours.

4. Natural Light Integration

Utilizing skylights and translucent roofing panels can supplement artificial lighting, reducing energy consumption and creating a well-lit environment during daylight hours.

5. Task-Specific Lighting

For areas requiring precision, such as inspection stations or packing zones, focused task lighting ensures workers can perform their duties accurately.

How to Choose the Right Warehouse Lighting

When selecting industrial lighting solutions for your warehouse, consider the following factors:

-

Ceiling height: Choose high bay or low bay fixtures depending on the ceiling height.

-

Lumen output: Ensure lights provide adequate brightness for the workspace.

-

Color temperature: Use neutral (4000K) to cool white (5000K-6500K) for optimal visibility.

-

Energy efficiency: Opt for LED lighting to reduce power consumption.

-

Control systems: Implement smart lighting solutions with dimmers and motion sensors for energy savings.

FAQs About Warehouse Lighting Requirements

1. What is the OSHA requirement for warehouse lighting?

OSHA does not specify exact lux levels but requires adequate lighting to ensure safety and prevent accidents. The IES standards are commonly followed.

2. What is the best lighting for a warehouse with high ceilings?

High Bay LED Lights are the best choice for warehouses with high ceilings, as they provide powerful illumination and efficiency.

3. How many lumens do I need for a warehouse?

A general storage warehouse requires 10-20 lumens per square foot, while work areas need 30-50 lumens per square foot.

4. What color temperature is best for warehouse lighting?

A color temperature of 4000K to 5000K is recommended for warehouse lighting, as it offers a bright, neutral white light that enhances visibility.

5. How can I reduce warehouse lighting costs?

Switching to LED warehouse lighting, using motion sensors, and integrating natural light can significantly cut energy expenses.

Conclusion

Choosing the right warehouse lighting improves safety, efficiency, and operational accuracy. high bay LED lights, motion sensors, and task lighting help create an optimized work environment. By following industry guidelines and selecting the best lighting solutions, warehouses can maintain productivity while reducing energy costs.

For expert guidance on selecting industrial lighting solutions, contact a professional lighting provider to evaluate your warehouse needs.