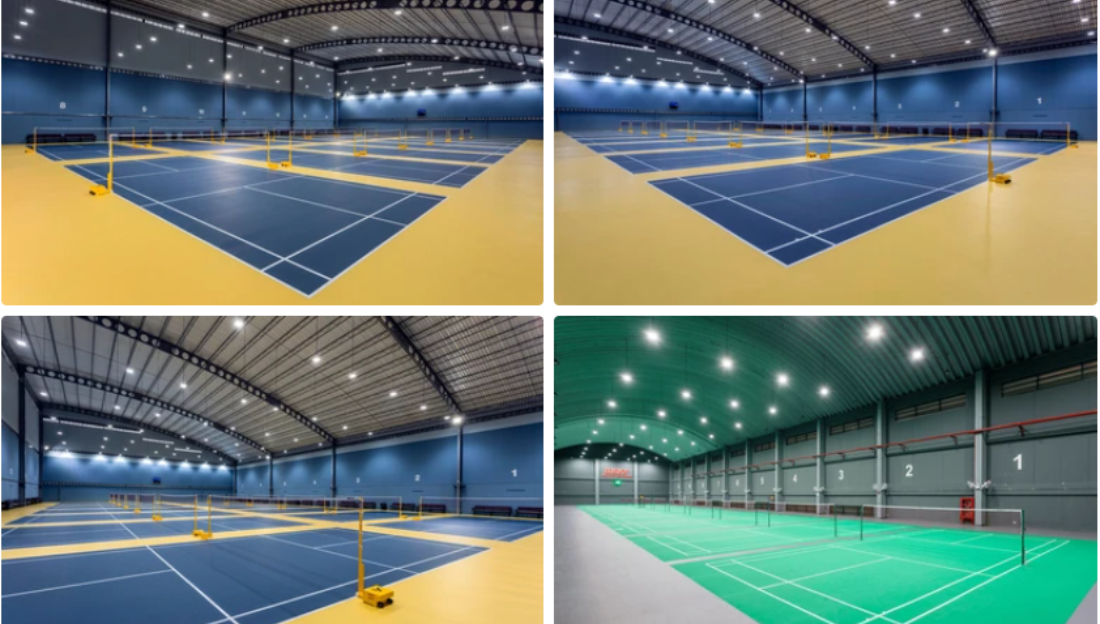

Warehouses are essential for storing, managing, and distributing goods efficiently. Proper lighting plays a critical role in warehouse operations, impacting productivity, safety, and energy efficiency. In this blog, we will explore the best lighting options for warehouses and highlight key factors to consider when choosing the right lighting system.

Why Proper Warehouse Lighting Matters?

According to the U.S. Occupational Safety and Health Administration (OSHA), poor lighting is one of the major causes of workplace accidents. Adequate warehouse lighting helps:

-

Reduce workplace accidents by improving visibility.

-

Enhance productivity by minimizing errors in picking and sorting.

-

Save energy and lower electricity costs with efficient lighting solutions.

-

Improve employee morale and comfort, reducing eye strain and fatigue.

Best Types of Lighting for Warehouses

1. LED Lighting

LED (Light Emitting Diode) lighting is the most preferred choice for warehouses due to its energy efficiency, longevity, and brightness.

Key Benefits of LED Lighting:

-

Energy Efficiency: Uses up to 75% less energy than traditional lighting.

-

Long Lifespan: Can last up to 50,000 hours or more, reducing maintenance costs.

-

Bright and Uniform Light: Provides consistent illumination without flickering.

-

Eco-Friendly: Contains no hazardous materials like mercury.

ex. High Bay Lighting (UFO LED High Bay Lights & Linear High Bay LED Lights)

High bay lighting is essential for warehouses with high ceilings, ensuring uniform illumination across large areas. Two popular types of high bay lights are UFO LED high bay lights and linear high bay LED lights.

UFO LED High Bay Lights:

-

Compact, circular design for high-intensity lighting.

-

Ideal for warehouses with ceilings above 13 feet.

-

Energy-efficient with excellent heat dissipation.

Linear High Bay LED Lights:

-

Rectangular shape for even light distribution.

-

Best suited for aisles and narrow warehouse spaces.

-

Provides uniform brightness with reduced glare.

2. High-Intensity Discharge (HID) Lights

HID lights, such as Metal Halide (MH) and High-Pressure Sodium (HPS) lamps, have been used for warehouse lighting for many years. However, they are being phased out due to their inefficiency.

Pros:

-

High brightness and good for high-ceiling warehouses.

-

Available in various wattages for different lighting needs.

Cons:

-

High energy consumption and heat emission.

-

Long warm-up time before reaching full brightness.

-

Requires frequent maintenance and replacements.

3. Fluorescent Lighting

Fluorescent lights, such as T5 and T8 tubes, are commonly used in warehouses with lower ceilings.

Advantages:

-

More energy-efficient than HID lamps.

-

Provides good illumination with minimal heat output.

-

Available in various color temperatures to suit different needs.

Disadvantages:

-

Shorter lifespan than LED lights.

-

May contain mercury, which requires proper disposal.

Factors to Consider When Choosing Warehouse Lighting

-

Ceiling Height: Higher ceilings require brighter and more powerful lighting solutions like UFO LED high bay lights and linear high bay LED lights.

-

Energy Efficiency: Choose lighting that reduces electricity costs and minimizes carbon footprint.

-

Color Temperature: For better visibility, opt for lights with a color temperature between 4000K-6000K (cool white to daylight).

-

Lighting Controls: Motion sensors, dimmers, and smart controls can optimize lighting and further reduce energy costs.

-

Durability: Warehouses require lighting that can withstand dust, vibrations, and temperature fluctuations.

How Much Light is Needed for a Warehouse?

According to the Illuminating Engineering Society (IES), warehouses require different lighting levels based on tasks:

-

General storage areas: 10-30 foot-candles.

-

Packing and sorting areas: 30-50 foot-candles.

-

Detailed assembly work: 50-100 foot-candles.

Proper lighting layout and spacing also play a crucial role in ensuring even illumination without shadows or dark spots.

Conclusion

Investing in the right warehouse lighting is essential for improving safety, efficiency, and operational costs. LED lighting remains the top choice due to its energy efficiency, longevity, and superior illumination. UFO LED high bay lights and linear high bay LED lights are particularly effective for high-ceiling warehouses, offering optimal brightness and coverage. However, factors like ceiling height, lighting controls, and durability should be considered when selecting the best lighting system for your warehouse.

Frequently Asked Questions (FAQs)

1. What is the best lighting for a warehouse with high ceilings?

UFO LED high bay lights and linear high bay LED lights are the best choices for warehouses with high ceilings as they provide bright, uniform illumination and consume less energy.

2. How can I reduce energy costs in my warehouse?

Switching to LED lighting, using motion sensors, and optimizing light placement can significantly lower energy consumption and reduce costs.

3. What is the recommended brightness for warehouse lighting?

The recommended brightness depends on the type of work being done, ranging from 10 foot-candles for general storage to 100 foot-candles for detailed tasks.

4. Are LED lights worth the investment for warehouses?

Yes, LED lights offer long-term savings by reducing energy costs and maintenance expenses, making them a cost-effective investment.

5. How long do warehouse LED lights last?

Warehouse LED lights can last up to 50,000 hours or more, depending on usage and maintenance.

By choosing the right lighting solution, warehouses can enhance safety, efficiency, and cost savings in the long run. Need help selecting the best lighting for your warehouse? Contact a professional lighting expert today!