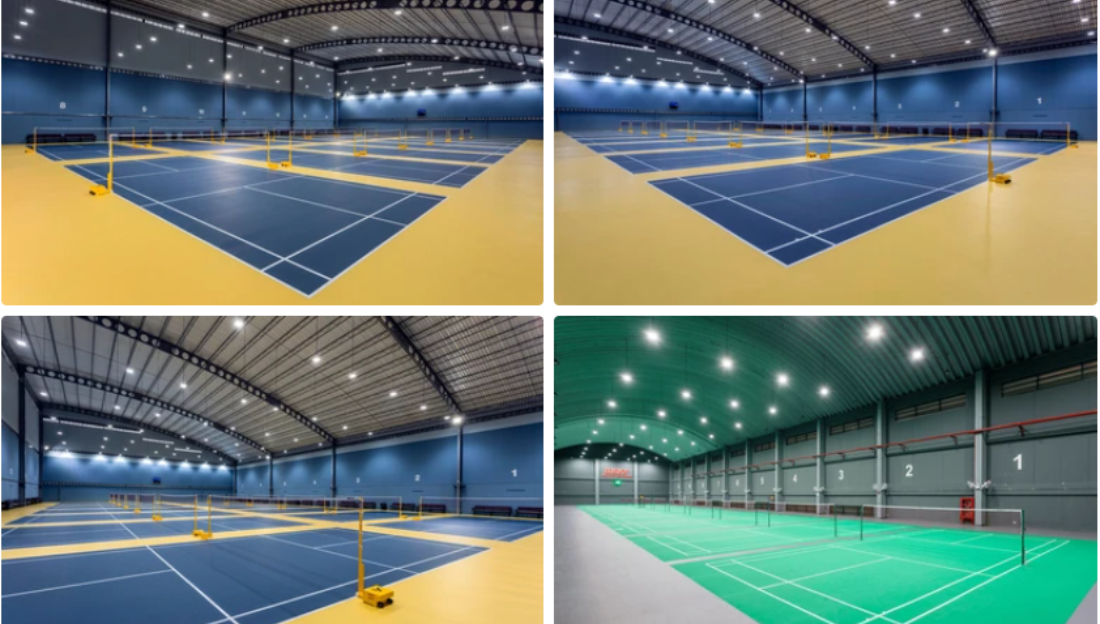

Efficient warehouse lighting is essential for productivity, safety, and energy savings. With technological advancements, warehouses now have multiple lighting options to choose from, each catering to specific needs. In this updated guide, we explore various types of warehouse lighting, their benefits, and key considerations.

1. LED Lighting

LED lighting has revolutionized warehouse illumination with its energy efficiency, long lifespan, and superior brightness. Benefits:

-

Energy savings up to 75% compared to traditional lighting

-

Longer lifespan (50,000+ hours)

-

Low maintenance costs

-

Eco-friendly (no mercury or harmful emissions)

Best For: General warehouse lighting, high bay areas, aisles, and workstations.

2. High-Intensity Discharge (HID) Lighting

HID lights, including metal halide and high-pressure sodium lights, were once a standard choice for warehouses. Benefits:

-

Bright, intense light output

-

Suitable for high ceilings

-

Good for large areas

Drawbacks:

-

Longer warm-up times

-

Higher energy consumption

-

Shorter lifespan compared to LEDs

3. Fluorescent Lighting

Fluorescent lights, particularly T5 and T8, are widely used in warehouses due to their affordability and decent energy efficiency. Benefits:

-

Good energy efficiency

-

Low initial cost

-

Provides uniform lighting

Best For: Office spaces within warehouses, picking and packing stations.

4. Induction Lighting

Induction lights are a lesser-known but effective lighting solution with a long lifespan and efficient energy use. Benefits:

-

Extremely long lifespan (100,000+ hours)

-

Consistent light output with minimal flickering

-

Low maintenance

Best For: Hard-to-reach warehouse areas where frequent maintenance is not feasible.

5. Motion Sensor & Smart Lighting

Smart lighting solutions incorporate motion sensors and automation to enhance efficiency. Benefits:

-

Reduces unnecessary energy consumption

-

Enhances security with motion-activated lighting

-

Customizable settings based on occupancy and time

Best For: Warehouses looking to optimize energy use and reduce costs.

6. Natural & Skylight Lighting

Incorporating natural light through skylights or translucent panels can complement artificial lighting. Benefits:

-

Reduces reliance on electrical lighting during the day

-

Improves worker well-being

-

Lowers energy costs

Best For: Warehouses in regions with ample daylight hours.

Comparison Table: Warehouse Lighting Options

| Lighting Type | Energy Efficiency | Lifespan (Hours) | Initial Cost | Best Application |

|---|---|---|---|---|

| LED Lighting | Very High | 50,000+ | Medium | General lighting, high bay areas |

| HID Lighting | Low | 10,000-25,000 | High | Large warehouses with high ceilings |

| Fluorescent | Medium | 15,000-30,000 | Low | Office spaces, task areas |

| Induction | High | 100,000+ | High | Hard-to-reach areas |

| Motion Sensor & Smart Lighting | Very High | Varies | Medium to High | Energy-conscious warehouses |

| Natural Lighting | N/A | N/A | Varies | Daylight-rich environments |

Final Thoughts

Choosing the right Warehouse Lighting depends on factors like energy efficiency, maintenance costs, and specific operational needs. LED lighting remains the top choice for most warehouses, but combining multiple solutions, including motion sensors and natural lighting, can yield the best results. Investing in the right lighting not only improves safety and productivity but also leads to long-term cost savings.