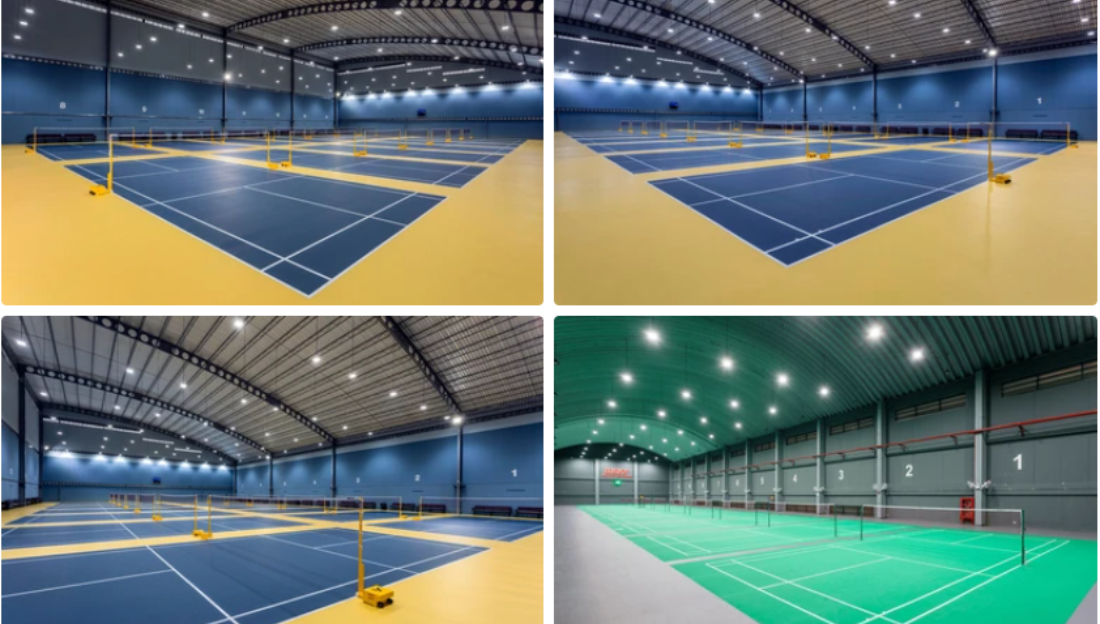

Proper lighting in a warehouse is essential for safety, efficiency, and productivity. Whether you're setting up new lighting or upgrading an existing system, understanding how to calculate the right amount of lighting is crucial. In this blog, we’ll break down the process in a simple and user-friendly way.

Step 1: Determine the Purpose of the Warehouse

Different warehouses have different lighting needs based on their function. Consider these common categories:

-

Storage Warehouses – Require moderate lighting for navigation and stock management.

-

Manufacturing Facilities – Need brighter lighting to ensure precision and safety.

-

Distribution Centers – Demand even and consistent lighting to facilitate rapid movement of goods.

Step 2: Understand Key Lighting Terms

Before calculating lighting, familiarize yourself with these important terms:

-

Lumens (lm): Measures the total visible light output from a source.

-

Lux (lx): Measures illuminance, or how much light falls on a surface (1 lux = 1 lumen per square meter).

-

Foot-candles (fc): Another unit of illuminance (1 fc = 10.76 lux).

Step 3: Determine Recommended Light Levels

Here are general lighting recommendations based on warehouse functions:

-

General Storage: 10-30 fc (100-300 lux)

-

Packing Areas: 30-50 fc (300-500 lux)

-

Assembly/Inspection Areas: 50-100 fc (500-1000 lux)

Step 4: Calculate the Required Lumens

To find out how much light you need, use this formula:

Total Lumens Required = Desired Lux Level × Warehouse Area (in square meters)

For example, if your warehouse is 500 square meters and requires 300 lux, the calculation is: 500 × 300 = 150,000 lumens

Step 5: Choose the Right Fixtures and Spacing

Selecting the correct fixtures depends on ceiling height, type of work, and uniformity of lighting. Common choices include:

-

High Bay LED lights for ceilings above 20 feet.

-

Low-bay LED lights for ceilings below 20 feet.

-

Linear LED fixtures for aisle lighting.

Step 6: Consider Energy Efficiency and Controls

To optimize energy use, consider:

-

LED lighting (energy-efficient and long-lasting)

-

Motion sensors to reduce unnecessary usage

-

Dimmable fixtures to adjust lighting as needed

Step 7: Conduct a Lighting Simulation or Test

Before finalizing, it’s best to simulate the setup using lighting design software or test a small section to ensure brightness and coverage meet your needs.

Final Thoughts

Calculating Warehouse Lighting doesn’t have to be complicated. By following these steps and considering the warehouse’s function, size, and efficiency, you can create a well-lit and productive workspace. Investing in the right lighting not only improves safety but also enhances workflow and reduces long-term costs.

Need help choosing the best lighting solution? Reach out to a professional lighting consultant for expert guidance!