Proper lighting in a factory is crucial for ensuring productivity, safety, and energy efficiency. The right lighting system can reduce eye strain, prevent accidents, and enhance the overall work environment. In this guide, we will explore the best lighting solutions for factories, their benefits, and tips for choosing the right setup.

Types of Factory Lighting

Factories require different types of lighting depending on the nature of work and layout. Here are the most commonly used factory lighting types:

1. LED Lighting

-

Energy-efficient and long-lasting

-

Reduces maintenance costs

-

Provides bright, clear illumination

-

Includes various types such as:

-

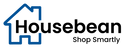

UFO LED High Bay Lights – Ideal for high-ceiling factories and warehouses, compact disc-shaped design for even light distribution, high lumen output, and glare-free illumination.

-

Linear LED High Bay Lights – Suitable for large open areas, offering uniform light coverage and easy installation.

-

Panel LED Lights – Best for office and cleanroom environments within a factory, providing soft and uniform light.

-

2. Fluorescent Lighting

-

Commonly used for large spaces

-

More efficient than traditional incandescent bulbs

-

Ideal for general lighting applications

-

Examples include T5 and T8 fluorescent tubes which offer moderate efficiency and cost-effectiveness.

3. High-Intensity Discharge (HID) Lighting

-

Used for high-ceiling spaces

-

Provides powerful illumination

-

Can take time to reach full brightness

-

Includes Metal Halide, High-Pressure Sodium, and Mercury Vapor lights, each with varying brightness levels and applications.

4. Halogen Lighting

-

Produces bright and white light

-

Good for task lighting

-

Higher energy consumption

-

Often used in spotlights and floodlights for targeted lighting.

5. Natural Lighting

-

Utilizes skylights and large windows

-

Reduces artificial lighting costs

-

Enhances employee well-being

-

Works best in combination with reflective surfaces and daylight harvesting systems.

Comparison Table: Best Lighting Options for Factories

| Lighting Type | Energy Efficiency | Lifespan | Best Use Case |

|---|---|---|---|

| LED | High | 50,000+ hours | General and task lighting |

| UFO LED High Bay Lights | High | 50,000+ hours | High-ceiling areas and warehouses |

| Linear LED High Bay Lights | High | 50,000+ hours | Large open factory floors |

| Panel LED Lights | High | 50,000+ hours | Offices and cleanrooms within factories |

| Fluorescent (T5/T8) | Moderate | 10,000-20,000 hours | Large areas |

| HID (Metal Halide, HPS) | Moderate | 24,000+ hours | High-ceiling areas |

| Halogen (Spotlights) | Low | 2,000-4,000 hours | Task-specific lighting |

| Natural Light | Very High | Unlimited | Daytime operations |

Key Factors to Consider When Choosing Factory Lighting

-

Brightness (Lumens) – Ensure lighting is adequate for tasks performed.

-

Energy Efficiency – Choose LEDs or natural lighting to reduce electricity bills.

-

Durability – Long-lasting lighting reduces maintenance costs.

-

Safety Compliance – Follow workplace lighting standards and OSHA regulations.

-

Color Temperature – Choose appropriate warmth or coolness of light based on the work environment.

Tips for Effective Factory Lighting

-

Use Motion Sensors to save energy in low-traffic areas.

-

Install Reflective Surfaces to enhance light distribution.

-

Consider Smart Lighting Systems for automated control and monitoring.

-

Regular Maintenance to prevent flickering lights and maintain brightness.

-

Layer Lighting by combining general, task, and accent lighting for maximum efficiency.

Frequently Asked Questions (FAQs)

1. Why is factory lighting important?

Factory lighting enhances worker safety, reduces eye strain, and improves productivity by providing adequate illumination for tasks.

2. What is the best lighting option for energy savings?

LED lighting, especially UFO LED High Bay Lights, is the best choice for energy efficiency, long lifespan, and reduced maintenance costs.

3. How can natural light be utilized in a factory?

Natural light can be incorporated through skylights, large windows, and reflective surfaces to reduce reliance on artificial lighting.

4. What are the recommended brightness levels for factories?

General factory lighting should be around 300-500 lux, while task lighting should be 750-1,000 lux, depending on the precision required.

5. How often should factory lights be replaced?

It depends on the type of lighting used. LEDs last up to 50,000 hours, while halogen bulbs may need replacement within 2,000-4,000 hours.

Conclusion

Selecting the right lighting for a factory is essential for efficiency, safety, and cost savings. Among LED lighting options, UFO LED High Bay Lights stand out for their ability to illuminate high-ceiling spaces efficiently, making them ideal for factories and warehouses. Additionally, Linear LED High Bay Lights and Panel LED Lights offer further flexibility for different factory settings. LED lighting remains the best choice for most industrial environments due to its durability and energy efficiency. However, incorporating natural light and smart controls can further enhance factory lighting effectiveness. By considering key factors and following best practices, businesses can create a well-lit, productive workspace.