Proper lighting is a crucial element in industrial warehouses. It not only enhances safety and efficiency but also boosts productivity and reduces energy costs. Whether you are setting up a new warehouse or upgrading your existing lighting system, this guide will help you make informed decisions.

Why Warehouse Lighting Matters

1. Safety

A well-lit warehouse reduces the risk of accidents and injuries. Poor lighting can cause slips, trips, and falls, especially in high-traffic areas.

2. Productivity

Adequate lighting helps employees work efficiently by reducing eye strain and enhancing visibility in all areas of the warehouse.

3. Energy Efficiency

Modern lighting solutions, such as LED lights, consume less energy and have a longer lifespan compared to traditional lighting systems.

4. Regulatory Compliance

Many industries have specific lighting standards that must be met to ensure a safe working environment.

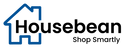

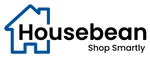

Types of Warehouse Lighting

1. LED Lighting

LED lights are the most energy-efficient and durable option for warehouses. They provide bright illumination, consume less power, and require minimal maintenance. The best LED lighting options for warehouses are high bay LED lights, which are available in two types:

-

UFO LED High Bay Lights – Compact, round fixtures ideal for high-ceiling warehouses.

-

Linear High Bay LED Lights – Rectangular fixtures that provide even light distribution over large areas.

2. High-Intensity Discharge (HID) Lighting

HID lights, such as metal halide and high-pressure sodium lamps, were once popular for warehouse lighting. However, they take time to warm up and consume more energy compared to LEDs.

3. Fluorescent Lighting

Fluorescent lights offer good brightness and are more energy-efficient than HID lights but still fall short when compared to LEDs.

4. Natural Lighting

Skylights and large windows can help reduce reliance on artificial lighting during the day, lowering electricity costs.

Key Considerations for Choosing Warehouse Lighting

| Factor | Description |

|---|---|

| Brightness (Lumens) | Warehouses typically require 300-500 lumens per square meter. |

| Color Temperature | 4000K-5000K provides a bright, daylight-like environment. |

| Lighting Layout | Ensures even light distribution, eliminating dark spots. |

| Motion Sensors | Helps reduce energy consumption by turning lights off when unoccupied. |

| Durability | Choose fixtures that require minimal maintenance. |

Tips for Improving Warehouse Lighting

-

Replace outdated lighting systems with LEDs to save on energy costs.

-

Use reflectors and diffusers to enhance light distribution.

-

Ensure emergency lighting systems are in place for power outages.

-

Regularly clean and maintain lighting fixtures to maintain optimal brightness.

-

Consider motion sensors and automation to reduce energy consumption.

FAQs

1. What are the best lights for a warehouse?

High bay LED lights, including UFO and Linear high bay LED lights, are the best options due to their efficiency and brightness.

2. How many lumens do I need for a warehouse?

Warehouses typically require 300-500 lumens per square meter for adequate illumination.

3. Are LED lights better than fluorescent or HID lights?

Yes, LED lights consume less power, last longer, and provide better illumination compared to fluorescent and HID lights.

4. How can I reduce energy costs in my warehouse lighting?

Use LED high bay lights, motion sensors, and automated controls to optimize energy usage.

5. What is the lifespan of LED warehouse lighting?

LED lights can last 50,000 hours or more, reducing maintenance and replacement costs.

Conclusion

Proper warehouse lighting is essential for maintaining a safe, productive, and energy-efficient workplace. Investing in modern lighting solutions like LEDs, utilizing automation, and strategically planning your lighting layout can significantly enhance your warehouse operations. By making smart lighting choices, you can improve working conditions and save on energy costs in the long run.

Need help choosing the right lighting for your warehouse? Contact an expert today!